QUALITY IS A MUST FOR TIMELESS PRODUCTS AND COLLECTABLES SO IT WAS REALLY IMPORTANT TO SEEK QUALITY ABOVE EVERYTHING.

THE MOST PROMINENT DESIGN DETAILS + FEATURES ARE DIRECTLY INFLUENCED BY THE COLLECTING I HAVE DONE OVER THE YEARS.

THE TOOLS I USE TO ACHIEVE TOP QUALITY ARE A MIX OF HAND GUIDED MACHINES AND THE MOST UP TO DATE PRINTING TECHNOLOGY

“IN 50 YEARS I WANT A KID TO FIND MY PIECES IN GARAGE SALE AND BE INSPIRED, THE SAME WAY I WAS”

CIRCLE G

HANDSTAMPED ON PROTOTYPES MADE IN THE GARAGE STUDIO.

ECO SILVER

POST CONSUMER SILVER HELPS REDUCE SURFACE MINING.

STAINLESS STEEL

RECYCLED STEEL IS CORE TO CIRCULAR DESIGN.

GLOSSARY

BALL BACK

The Ball Back directs the movement of the entire piece. Its patent pending shape is fully adjustable to dial in the perfect heel to toe fit and makes up the rear half of the insert.

SHOE PAPER

Shoe Paper is hand sculpted to resemble the paper that comes in the toe of most new shoes. Shoe Paper is a call for sustainability aimed at limiting the use of paper stuffing.

ROD

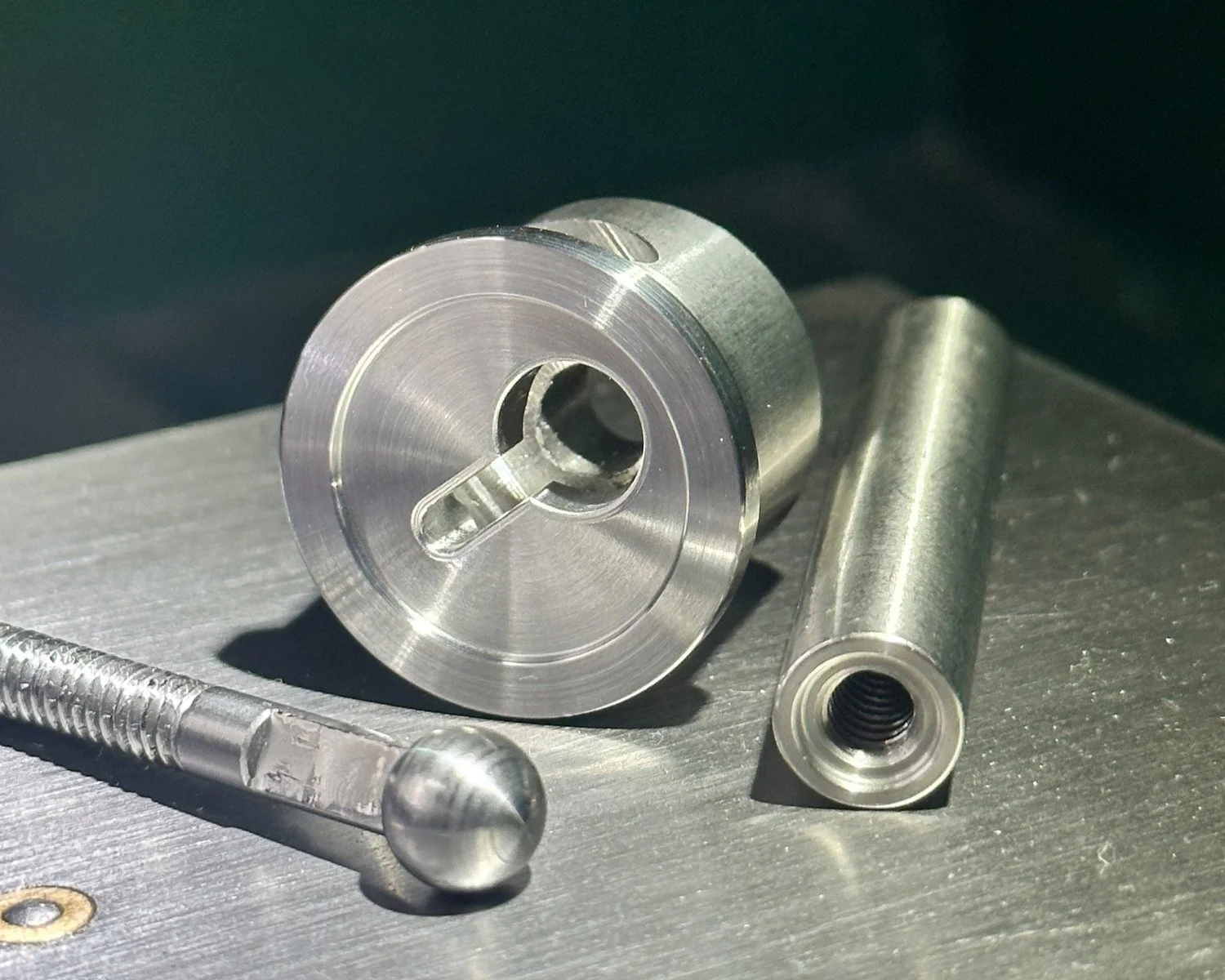

The front of the Rod drops into the Case and locks into place rotationally. The back of the Rod threads into the Cylinder allowing the Ball Back to adjust in length.

GARAGE

The Garage Studio is located in Los Angeles and houses everything from concept to production. Large machines take up significant room so this space will be the beginning and end of an era.

CAP

The cap is on the end of the Ball Back. Typically made of metal or resin its designed to help the ball back drop into your shoe with a nice “pop”, often has a button in the middle.

BUTTON

Located in the center of the Cap or Cases, Buttons are small circles typically stamped with a custom logo. They can be made of .999 silver or 303 Stainless Steel.

CYLINDER

Threaded to allow for precise heel to toe adjustment the Cylinder is the engine of the insert. Its also adds rigidity and a touch of craftsmanship on C-Through Neck options.

PROTOTYPE

Currently all pieces are marked “Prototype” with a stamp or CNC machine. This designation marks products with experimental ideas that may end up of retail or production models in the future.

GARAGE BUTTON

The Circle G is used to mark products that are completely hand made in the Garage Studio. The garage studio utilizes all types of machinery to make the highest quality product.

CASE

The Case connects the Ball Back to the Form with a spring loaded locking mechanism. Its designed to allow the user to switch ball backs between their favorite pieces.

LATHE

One of the pieces of heavy machinery in the Garage Studio the Lathe is a versatile tool used to create many parts by hand. I like to use a Grizzly lathe at this stage in development.

3D PRINTER

We push the boundaries of traditional product design and that means using innovative production methods. All Forms are 3d printed freeing me from the constraints of injection molding.